-

- Business Introduction

- Assembly Equipment

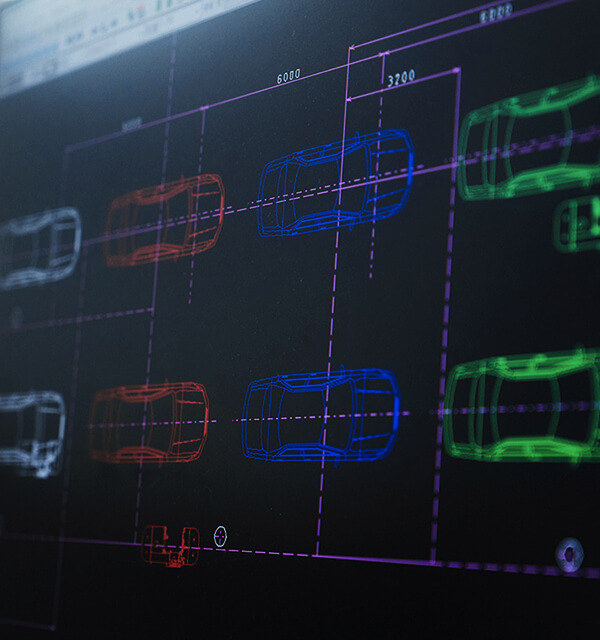

Facility Equipment Business Division ASSEMBLY Assembly Equipment

New business ventures

In 1970, during the high-growth period of the Japanese economy,Shinmei began its journey by working with the Toyota Motor Corporation to renovate vehicle assembly factories. At the time, Toyota was looking to increase its production volume to compete with European and American manufacturers. This is how our assembly equipment business first began. Shinmei took on the challenge by sending designers for training to Toyota to improve their technical capabilities. This knowledge allowed Shinmei to design and manufacture assembly equipment such as engine lifters and rear suspension lifters. Shinmei continued to develop rapidly, and our foray into assembly equipment was a major contributing factor to our success.

Feature

Features of our Business

Supporting the production of automobiles

with vehicle assembly line manufacturing

Shinmei manufactures production equipment for vehicle assembly lines in automobile manufacturing factories. We primarily focus on equipment that is installed in vehicles such as engines and rear suspensions. We are responsible for all production-related equipment that support the production of automobiles.

REASON

Reasons to Choose Us:

Toyota's Quality Development System

Our development process adheres to Toyota's standards and management know-how, giving us a competitive advantage in developing high-quality production equipment that other companies cannot easily replicate.

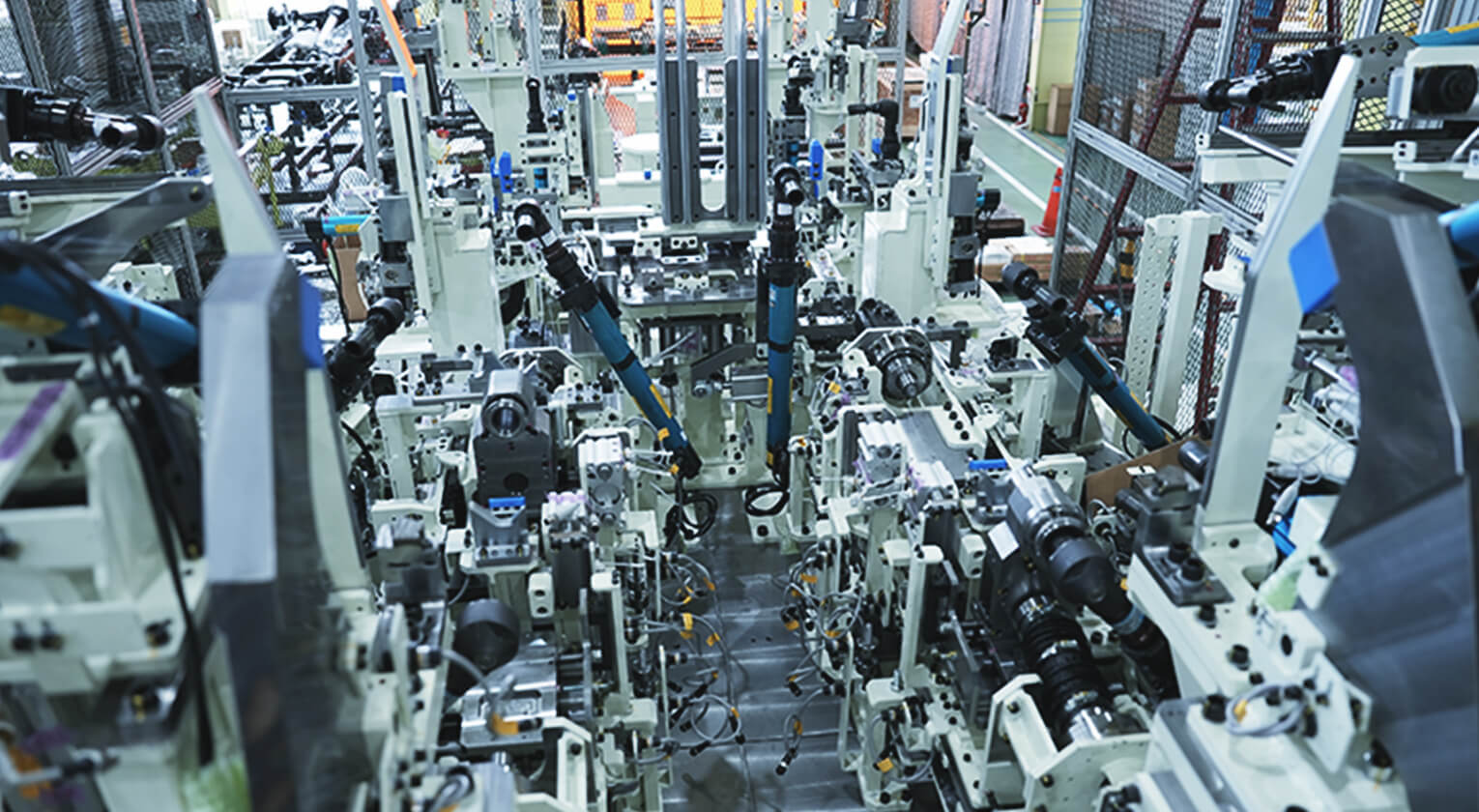

FACTORY LINE

Manufacturing Line

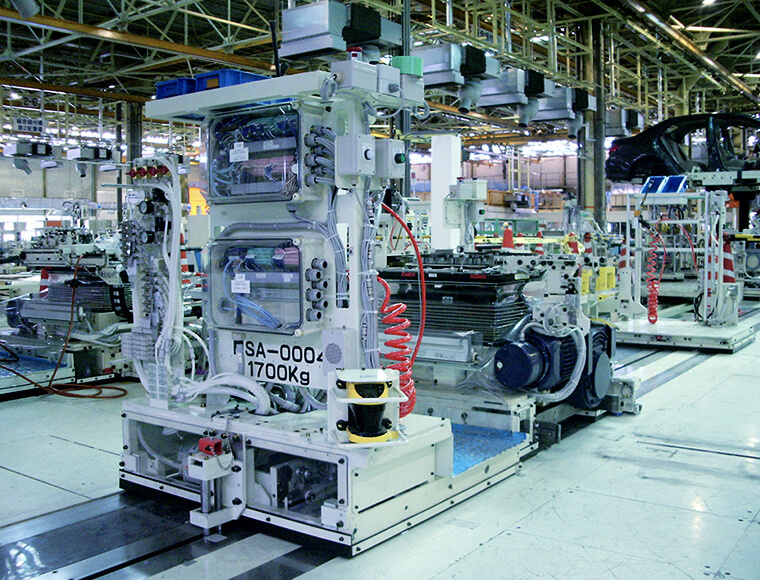

This is a line for assembling the undercarriage parts of a vehicle.

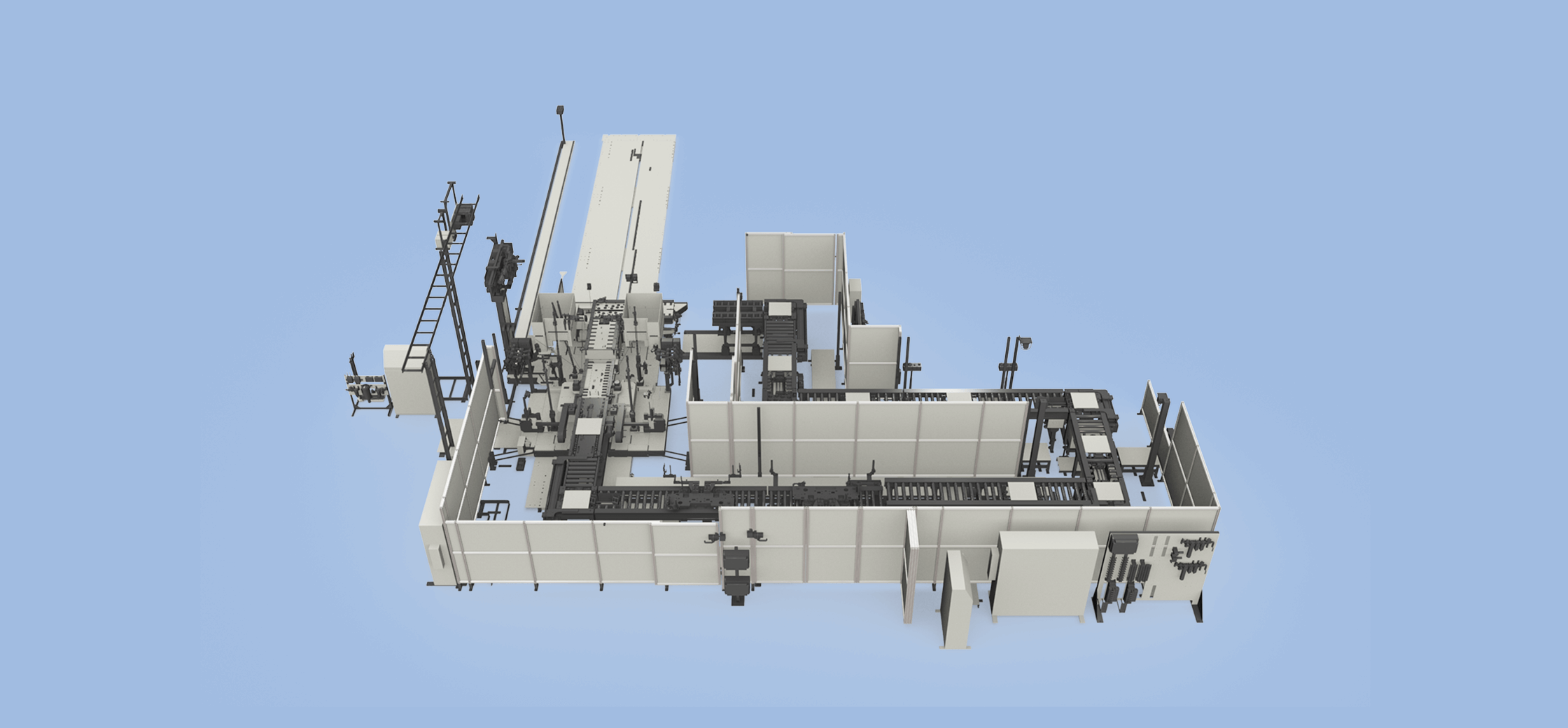

FACILITY

Facility outline

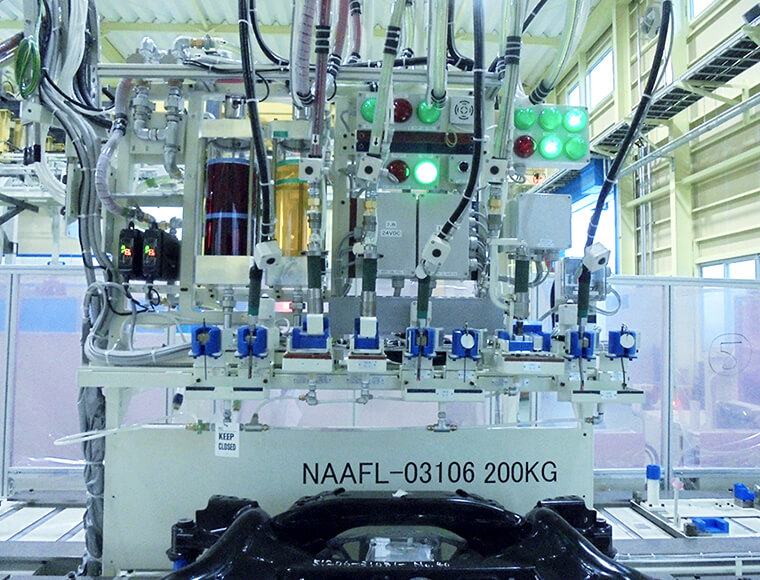

Rear Suspension Mounting Lifter

This equipment lifts the rear suspension assembly and mounts it onto the vehicle body.

Engine Mounting Lifter

This equipment lifts the engine and front suspension assembly, and mounts it onto the vehicle body.

Oil Filling Machine

This equipment is used to fill various types of oil into the transaxle, transfer case, differential, and other parts."

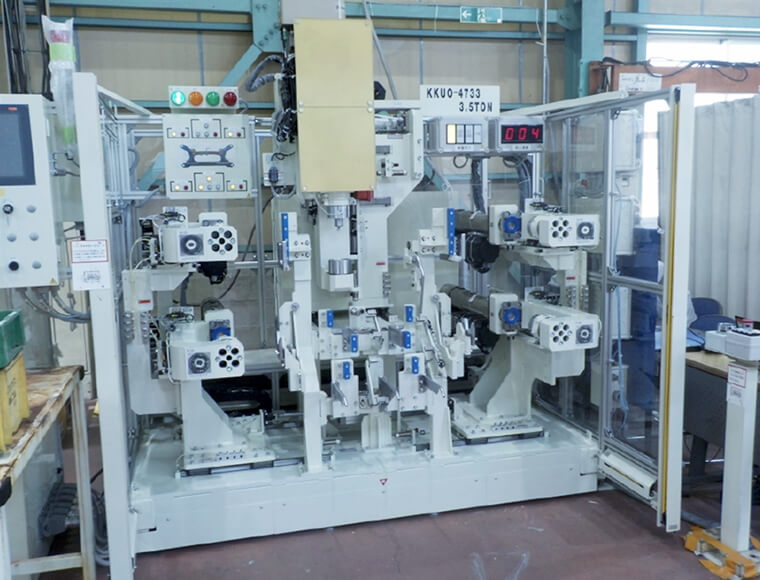

Bushing Press Machine

This equipment is used to press bushings (cushions) into the connection points between the front and rear suspension members and the body of the vehicle.

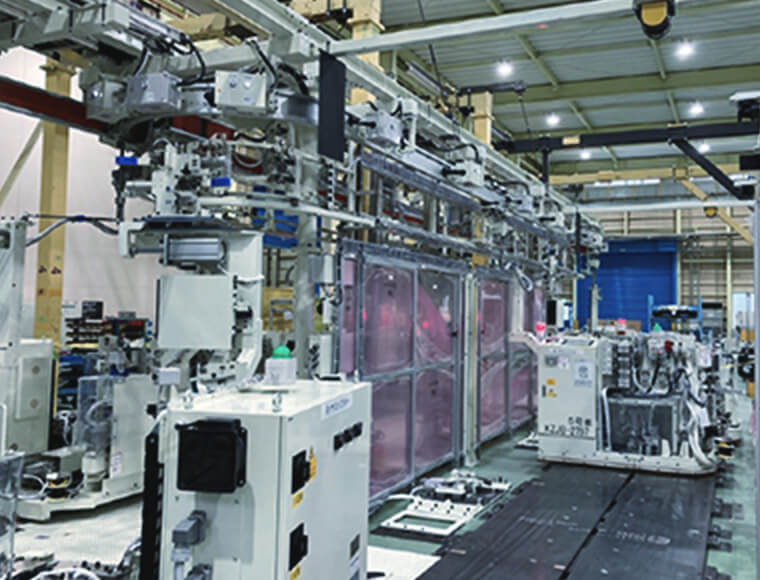

Ribbon Steel Conveyor

This is a conveyor that can accommodate various layout configurations within the factory. It connects the assembly trolley with ribbon steel, and can handle combinations of linkage and STOP & GO operations. (Patented product)

Front/Rear Suspension Tightening Machine

This is a machine that performs tightening operations (manual and automatic) for the body and undercarriage components.

Proven Track Record of Delivering to Top Automakers

Our company has delivered our products to a range of top automakers, including Toyota Motor Corporation's various plants, Toyota Industries Corporation, Toyota Auto Body Co., Ltd., Toyota Motor East Japan, Inc., Toyota Motor Kyushu, Inc., Hino Motors, Ltd., Daihatsu Motor Co., Ltd., Subaru Corporation, Daihatsu Motor Kyushu Co., Gifu Auto Body Co., Ltd., and Nissan Shatai Kyushu Co., Ltd. (in random order). Our ability to consistently meet the high standards of these companies demonstrates our commitment to excellence in product quality and customer service.

Overseas Delivery Results (Toyota Motor Corporation)

USA, Canada, Mexico, Argentina, Brazil, UK, France, Czech Republic, Turkey, China, India, Indonesia, Thailand, Taiwan, Vietnam

Future

Vision for the future

Supporting Other Businesses with Shinmei's Diversified Operations, including Electric Equipment

The goal of our assembly equipment is to contribute to the development of next-generation vehicles such as electric vehicles (EVs), fuel cell vehicles (FCVs), and hybrid vehicles (HVs). By taking on the responsibility of equipment development for these cutting-edge vehicles, we aim to support other businesses in this field and beyond.