Pacific War

During the war, the predecessor companies of Shinmei.

"Koromo Kamotsu Jidosha Unsou" and "Kamo Jidosha Kogyo", produced vehicles necessary for the war effort. Although passenger car production was prohibited for a while after Japan's defeat in 1945, Shinmei believed that the ban would be lifted eventually and strengthened its production system. This was proved right, when manufacturing was finally allowed in 1949. Being able to ride the wave of the subsequent development of the automotive industry was thanks to the careful preparation made at that time.

- Major Events & Achievements

-

- Increased the number of maintenance workshops for military vehicles in Aichi Prefecture

- Responded to the increasing maintenance requests as the war situation became more severe

- Members of the founding team of Toyota Motor Industries became directors

- The predecessor of Shinmei Industries, "Koromo Automobile Co., Ltd.," was established.

High Economic Growth

Unprecedented Car Boom.

However, there was no room for complacency.

In 1955, Japan entered a period of high economic growth and the economy boomed. With the opening of the Meishin Expressway and the Tomei Expressway, the car boom arrived. Shinmei Industries supported Toyota's production facilities by increasing its production of passenger cars and achieved rapid growth. However, there was no room for complacency. Anticipating an increase in demand for maintenance of private cars and logistics trucks, the company also actively invested in maintenance business. This vision proved to be accurate.

- Major Events & Achievements

-

- Responding to the increased demand for automobile maintenance due to mandatory vehicle inspections.

- Certified as a "Second-Class Heavy Maintenance Plant," which is a certification for excellent automobile maintenance factories issued by the Minister of Transport.

- As a result of improved recognition and trust, the company received orders for vehicle maintenance from Toyota.

- The President, Shinichi Ishikawa, was awarded the Medal with Yellow Ribbon, which is given to individuals who have contributed to the development of industry by the Emperor of Japan.

Oil Shock

Sales dropped by two-thirds.

The crisis that rocked the company was turned into an opportunity.

In 1973, the oil shock caused crude oil prices to skyrocket, affecting the automobile industry with increased gasoline prices and stricter emission regulations. New Meiko also suffered a crisis, with sales dropping from the 60 billion yen range to the 40 billion yen range. However, they saw the decrease in work as an opportunity and strengthened their cooperation with Toyota's production line, accumulating know-how that led to a competitive advantage in the future.

- Major Events & Achievements

-

- Shinmei established a system to produce conveyors without drawing from scratch

- In 1973, Shinmei opened a Nagoya sales office with three salespeople

- Shinmei established a special factory for mass-producing carrier trucks in 1977.

Bubble Economy

As Japan was enjoying a thriving economy, Shinmei was aggressively seeking growth opportunities.

Despite the record-high sales achieved by various companies during the bubble economy, Shinmei took on three new challenges: "overseas assembly" of optional accessories for vehicles exported abroad, massive capital investment in line with Toyota's sales plan, and resuming recruitment of talent which had been halted since the oil shock. Successfully meeting these challenges, Shinmei's sales of JPY 15.4 billion in 1985 doubled to JPY 27.1 billion six years later. The company's unyielding pursuit of growth had paid off.

- Major Events & Achievements

-

- The company won consecutive awards at the "All-Japan Automobile Mechanic Skills Competition" in 1980 and 1981.

- The company received the "Toyota Motor Corporation Quality Control Award" for outstanding suppliers that achieved results through quality management activities.

- The adoption of Toyota's manufacturing method significantly reduced production costs and improved quality standards.

- In 1982, the company won its first contract for vehicle restoration services.

Collapse of the Bubble Economy

With a solid defense and bold offense, Shinmei overcame the collapse of the bubble economy.

After the collapse of the bubble economy, car sales plummeted. In response, Shinmei launched the "SSK Operation," named after the initials of "Shinmei," "Slim," and "Kyoujin," meaning "smart," "slim," and "strong" respectively. This operation aimed to secure sales while streamlining production processes to improve the company's foundation. Despite the challenges of the period, such as the Great Hanshin-Awaji Earthquake and the extremely strong yen, the company was able to avoid falling into the red thanks to this strategy. Additionally, by taking on new challenges such as automating production facilities, the company prepared for an uncertain future.

- Major Events & Achievements

-

- To better align with Toyota's nationwide expansion, Shinmei established a Hokkaido factory in the Yubari district in 1992 and a Kyushu sales office in Munakata City, Fukuoka Prefecture in 1993.

- The company was a pioneer in promoting the automation of production facilities in response to the growing demand for such technologies.

- In 1996, Shinmei received the Toyota Technology Development Award for contributing to Toyota's product competitiveness with its "A-class press product high-speed loading device" developed that same year.

The Lehman Shock

The company faced its first deficit, but it paved the way for recovery through overseas expansion and the development of production facilities essential to next-generation cars.

In 2008, the Lehman Shock occurred. The US-based major automaker, General Motors, went bankrupt, and in Japan, Toyota faced its aftershocks. As a result, Shinmei Industry also experienced its first deficit since its establishment. However, the company recovered its management situation in 2013 through successful overseas expansion and the establishment of a new business division for next-generation cars. Despite the negative impact of the Lehman Shock, as well as events such as the increase in consumption tax and the US terrorist attacks, the company was able to survive due to its pioneering challenges.

- Major Events & Achievements

-

- In 2005, the company was responsible for maintaining the FC bus (liquid fuel cell) used in the Aichi Expo "Expo 2005 Aichi Japan".

- In 2009, the company launched the "Emergency Profit Improvement Project" to improve its management situation.

- In 2012, the company developed a new electronic adjustment machine for inspecting collision prevention devices that support safe driving.

Response to the Great

East Japan Earthquake

Around six months after the earthquake, a subsidiary was established in Tohoku, and efforts were made to support recovery.

On March 11, 2011, the Great East Japan Earthquake occurred. Following Toyota Motor Corporation's decision to relocate some production bases to Tohoku for the purpose of supporting recovery efforts, Shinmei Industries established "Shinmei Tohoku Co., Ltd." and began operating as a sales base. The company became a subsidiary rather than a mere sales office to contribute more deeply to the recovery efforts as a "locally-rooted company". Leveraging their cultivated technical and sales capabilities, they played a role in supporting recovery efforts from an economic perspective.

- Major Events & Achievements

-

- Established "Shinmei Tohoku Co., Ltd." in October 2011 for the purpose of supporting the recovery from the earthquake.

- Developed a new electronic adjustment machine for inspecting collision prevention devices that support safe driving in 2012, and delivered it to Toyota Motor Corporation's assembly plants.

- Held the first "Shinmei Product Exhibition" in 2013 to showcase the breadth of the company's business.

- Expanded their operations to the ASEAN region by establishing an office in Indonesia in 2014.

The COVID-19 Pandemic

The world came to a halt due to the outbreak of an unknown virus, and companies steered towards online platforms.

The outbreak of the novel coronavirus and the impact of the US-China trade dispute made it difficult to obtain parts, resulting in a decrease in orders for Shinmei Industries. However, the company utilized its surplus resources to invest in internal operations and digital transformation (DX) of its business. They transitioned from traditional face-to-face and phone communication tools to chat applications and consolidated disparate internal systems by unifying them. In addition, during the same period, they opened a non-contact, non-face-to-face car showroom called "SowZow". In order to turn an unprecedented crisis into an opportunity, they took bold new steps.

FUTURE

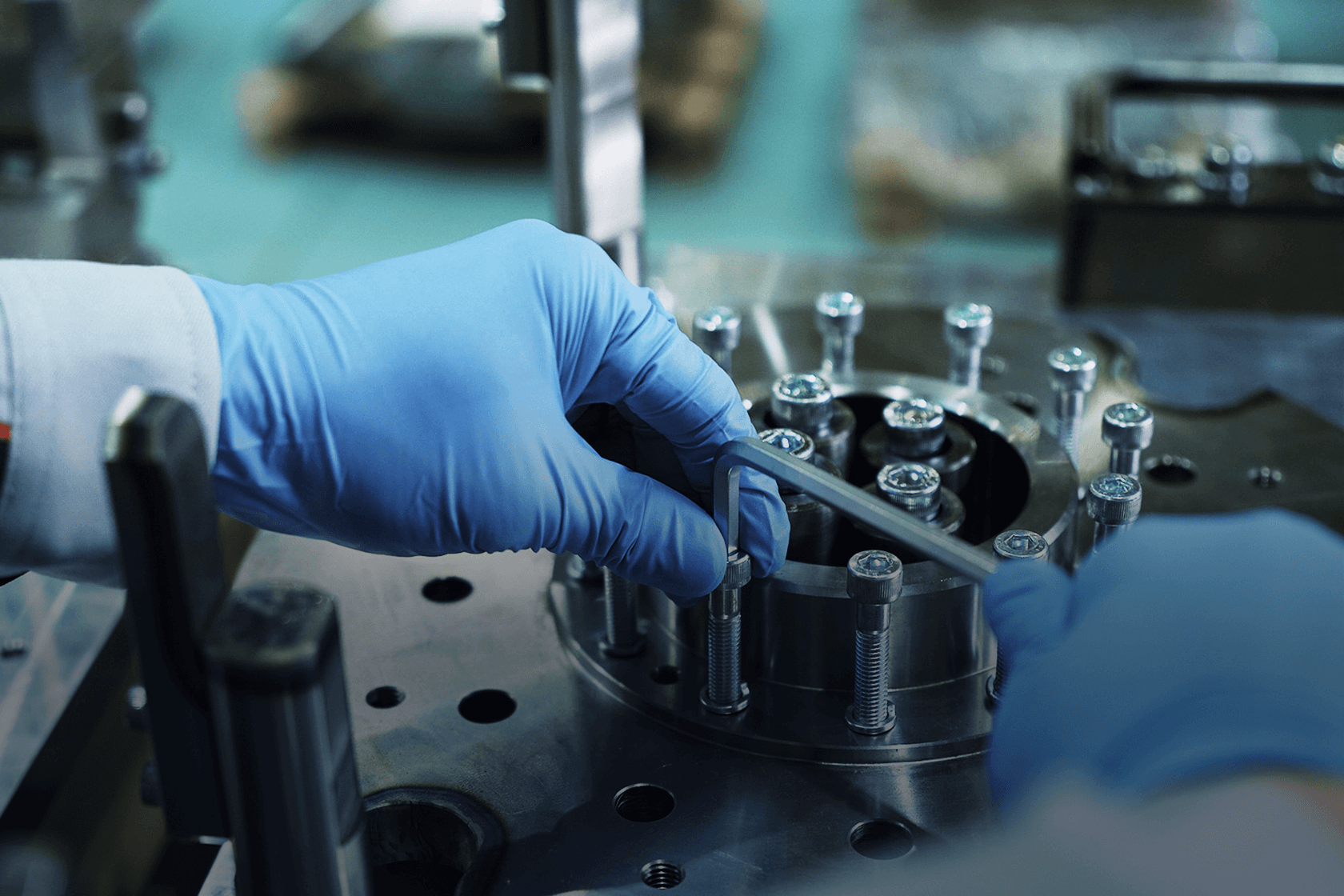

Pursuing the Future of Manufacturing

New challenges in a once-in-a-century era of transformation lie ahead. As we aim to become a leading manufacturer in this new age, we must continue to push the boundaries and build upon the spirit inherited from our predecessors.

With this driving force, we will establish our position as a manufacturer of the future.