-

- Business Introduction

- EV Business

Facility Equipment Business Division Motorized Electric Conversion Equipment

Shinmei's young engineers rise to

the challenge of the EV age.

In February 2011, Japan was still feeling the effects of the global financial crisis. Discussions surrounding pollution and fuel efficiency pushed large numbers of people into shifting from gasoline-powered cars to hybrids. Recognizing this as a turning point in the industry, Shinmei Industries made the decision to develop production equipment for electric vehicles. Shinmei established an Environmental Business Division and recruited project members within the company. Many enthusiastic engineers, particularly young talent, gathered to work on the development of "batteries", "inverters", and "motors". These dedicated individuals worked tirelessly to lay the foundation for electric vehicle production equipment.

Feature

Features of our Business

Innovative Production Facilities

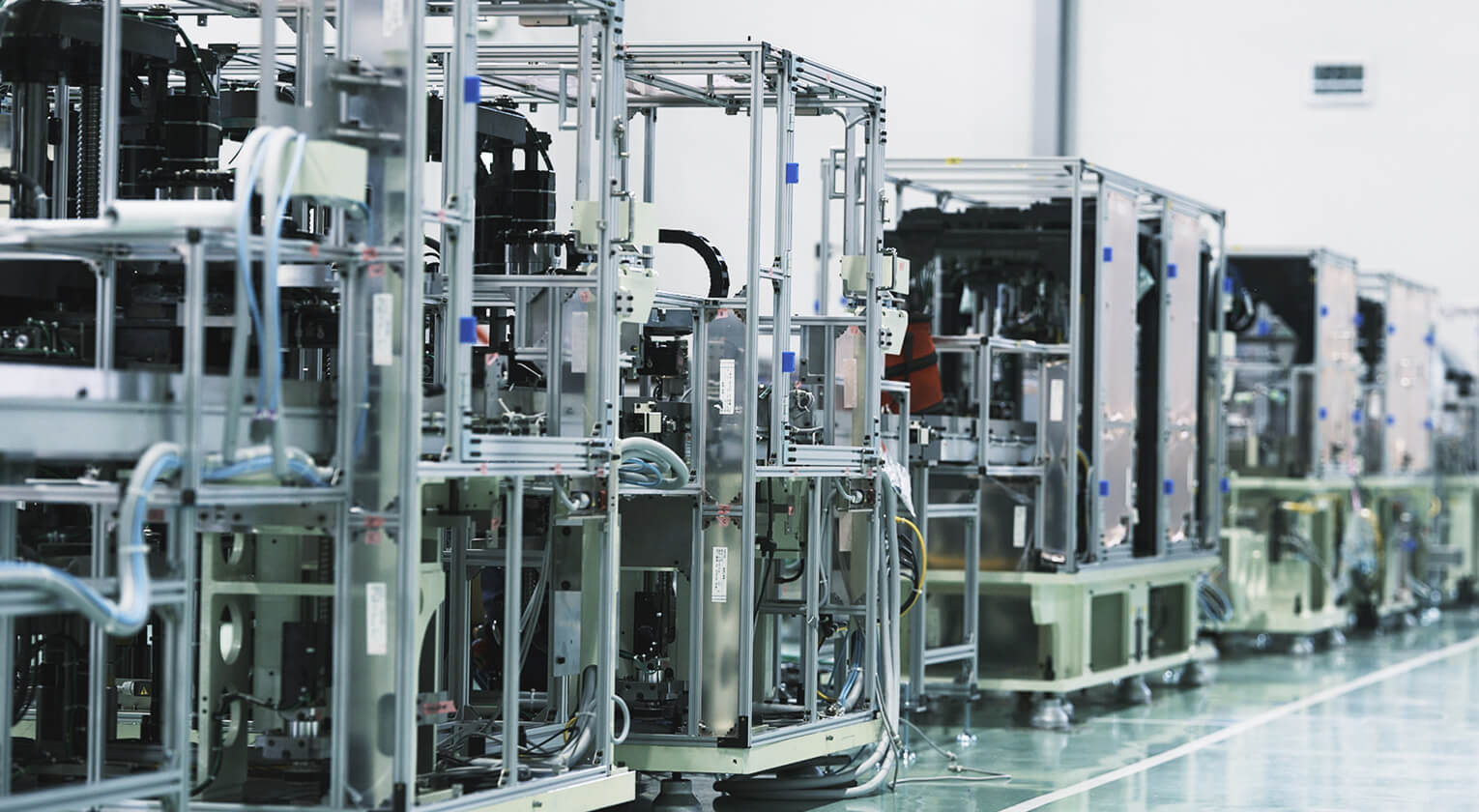

As the automotive industry moves towards EV's, with electric, hybrid, plug-in hybrid, and fuel cell vehicles becoming increasingly popular, Shinmei recognizes the need for cutting-edge production facilities to support this shift. By developing state-of-the-art production equipment for these new types of vehicles, we are committed to contributing to the advancement of the automotive industry into a new era.

REASON

3 reasons to choose Shinmei' products and services

Staying in tandem with Toyota's technology

Shinmei dispatches our engineers to Toyota's equipment development division to absorb practical know-hows for electric vehicle technology. This has enabled us to establish a highly advanced development system supported by the technical expertise we received under Toyota's guidance.

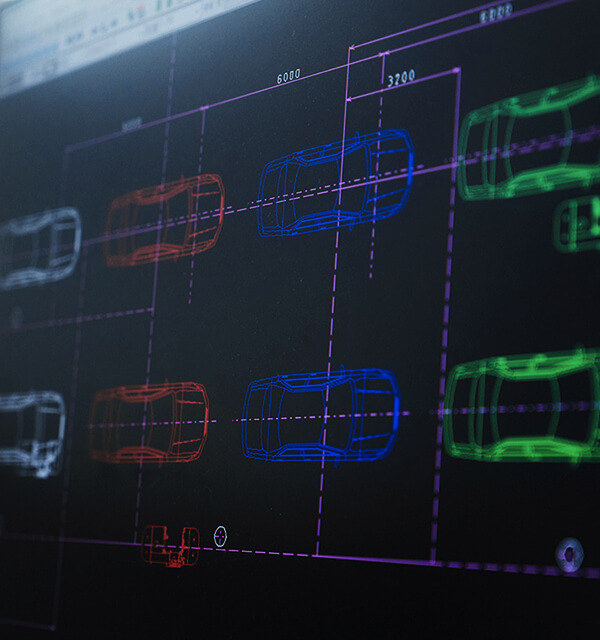

Maximizing 3D Technology: From Design to Assembly

We utilize 3D technology throughout the product development process, from design to assembly. We use 3DCAD for design, 3DCAM for machining, and 3D assembly support software for assembly, enabling us to deliver high-quality products with reduced lead times. With our diverse range of technologies and expertise, we are committed to maximizing the potential of 3D technology in our product development.

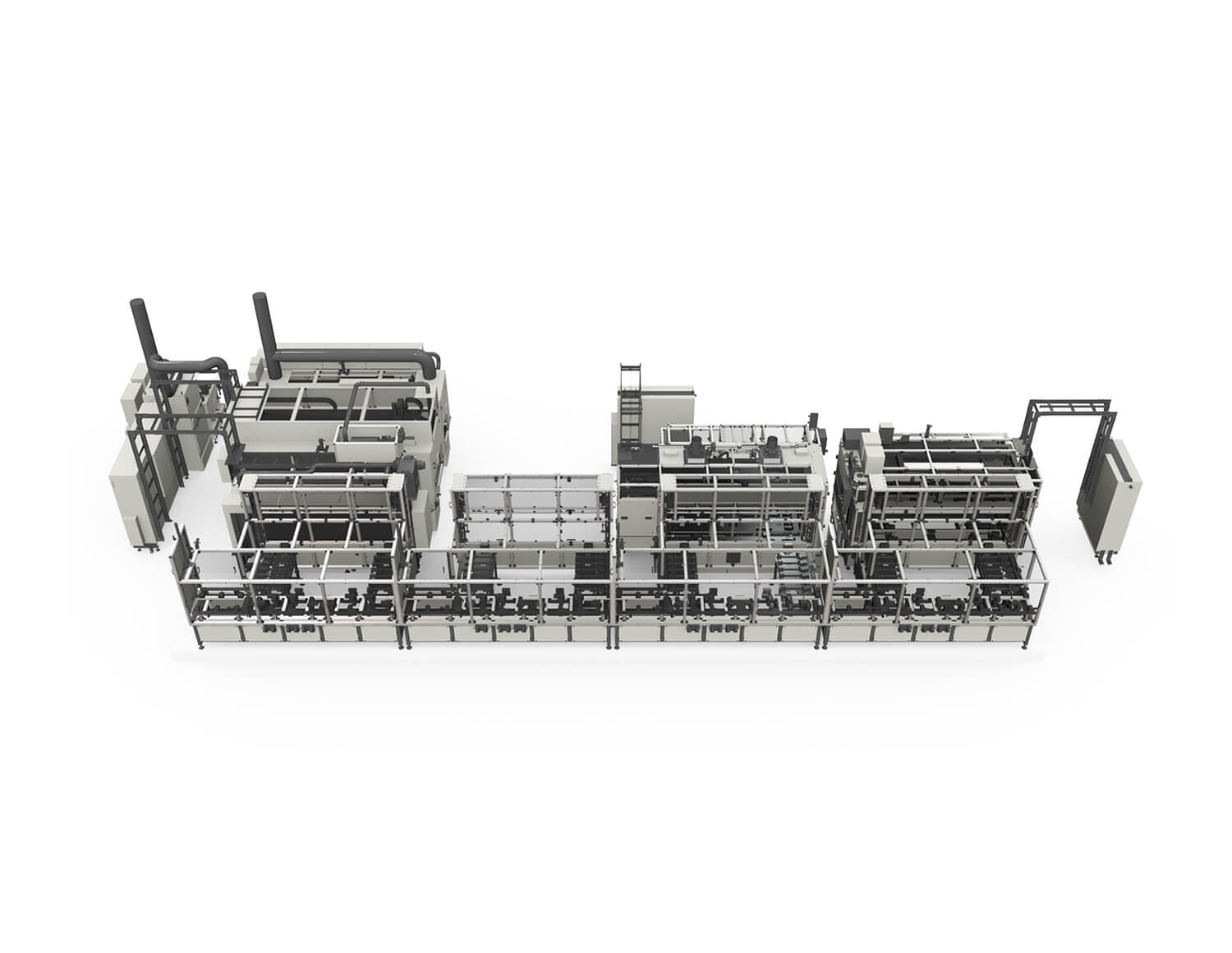

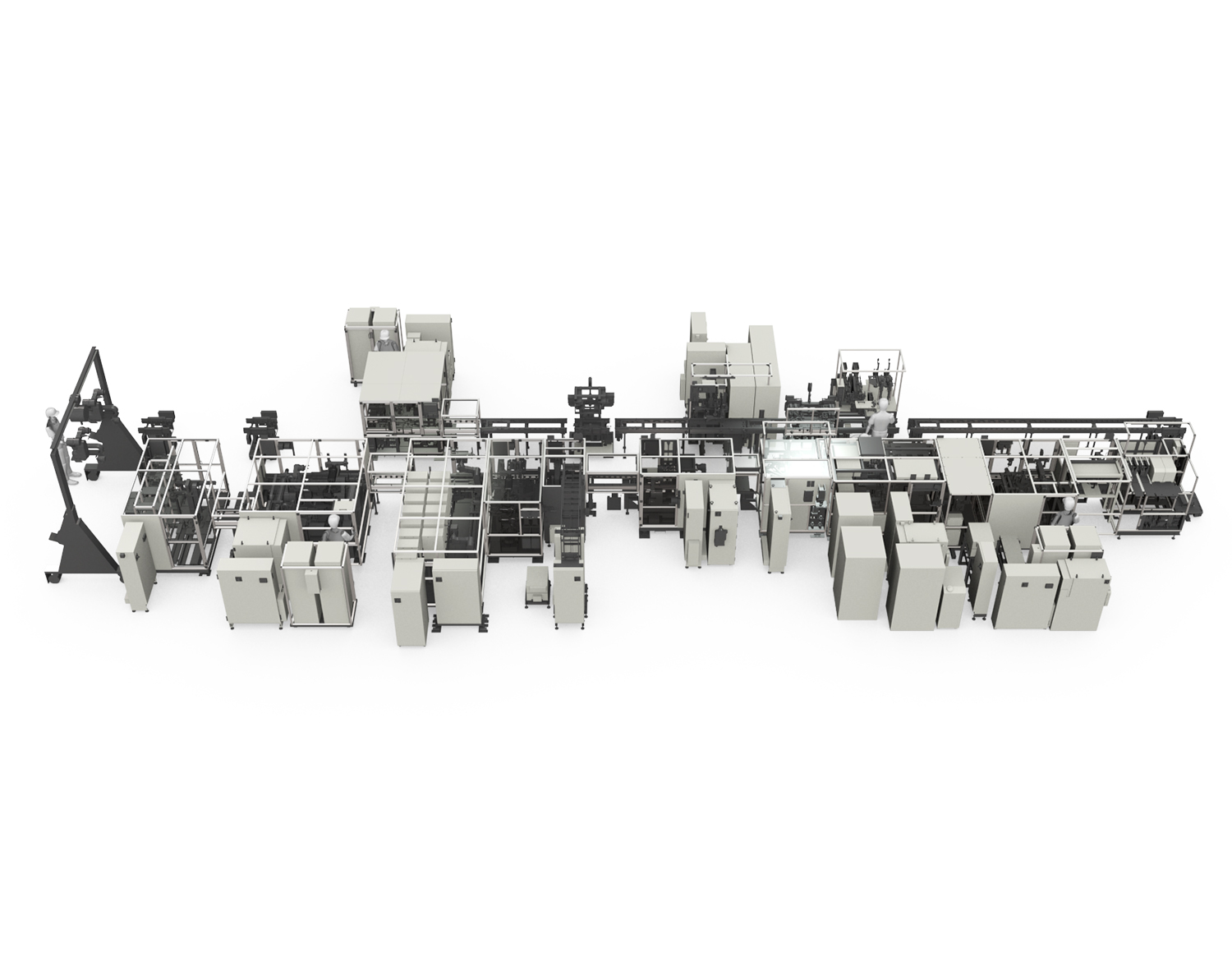

Modular Production Equipment

At Shinmei Industries, our production equipment is designed with modularization in mind, allowing for partial unit replacement to easily switch to new production areas. This unique feature leads to cost reduction and shorter lead times, giving us a competitive edge.

PRODUCTS

Product details

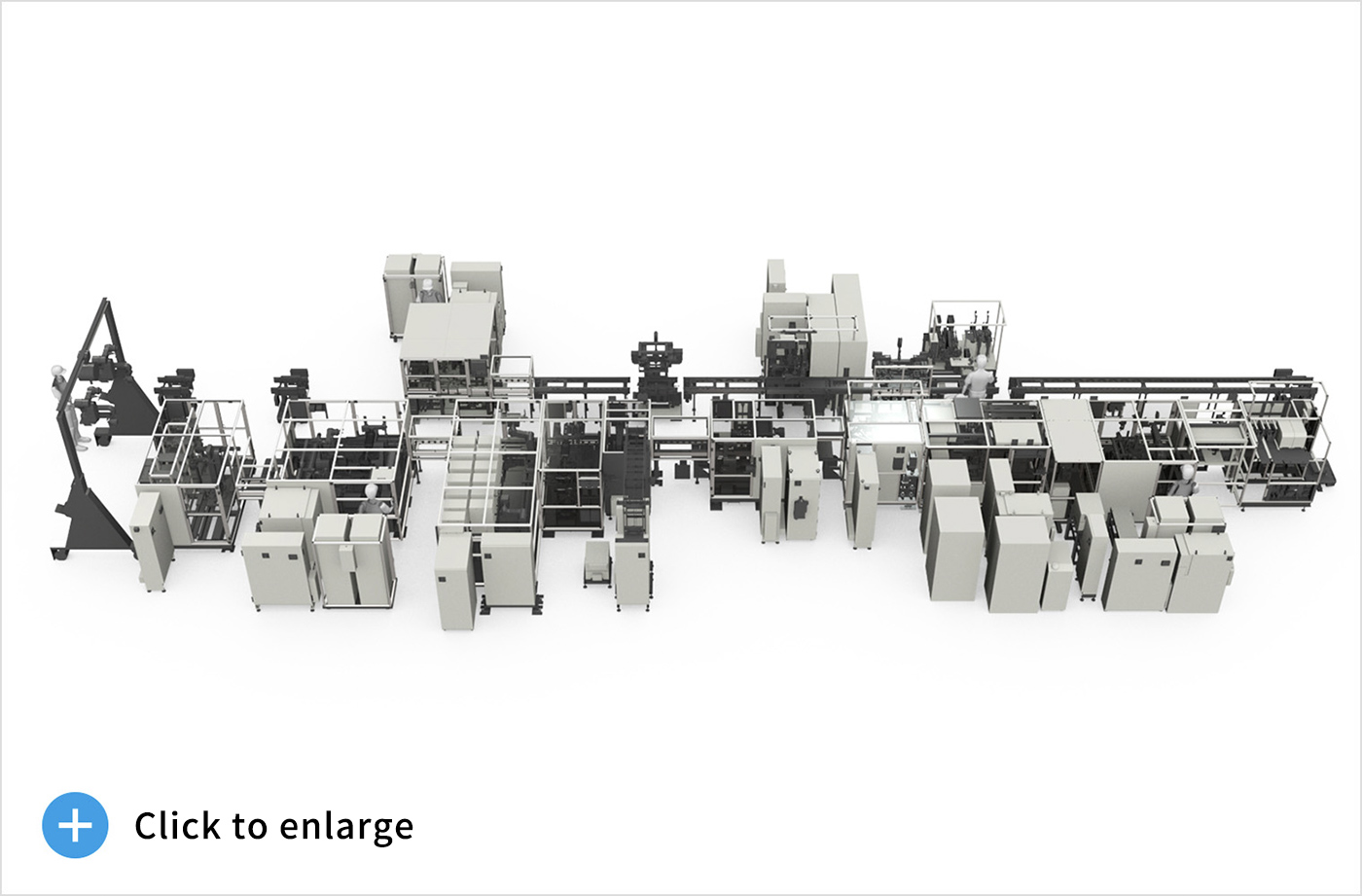

Inverter Equipment Line

Shinmei's Inverter Equipment Line is responsible for assembling inverters used to control the motors in hybrid and electric cars. It is equipped with automated parts supply, assembly, and product inspection capabilities for multiple components.

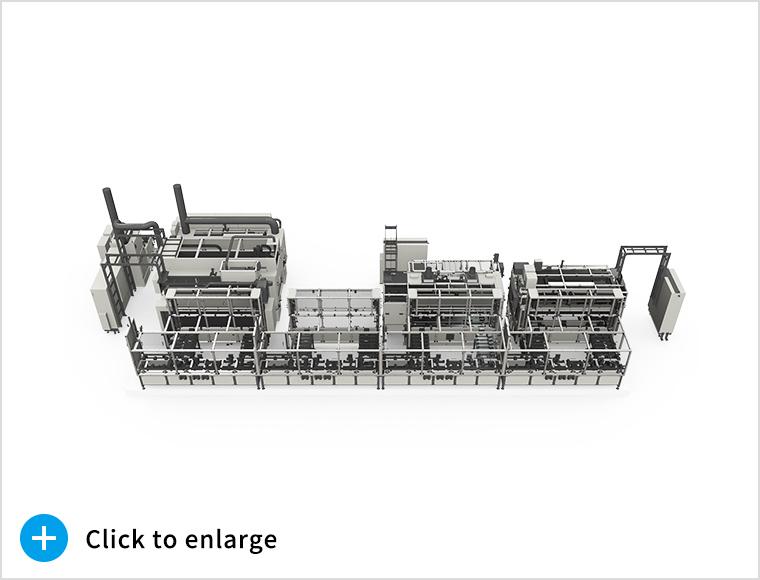

Hydrogen Tank Assembly Line

Shinmei's production line facility assembles hydrogen tanks used in fuel cell vehicles. The line applies an anti-adhesion agent to the tank surface, performs leak testing, measures the full-length dimension, and assembles sealing fixtures.

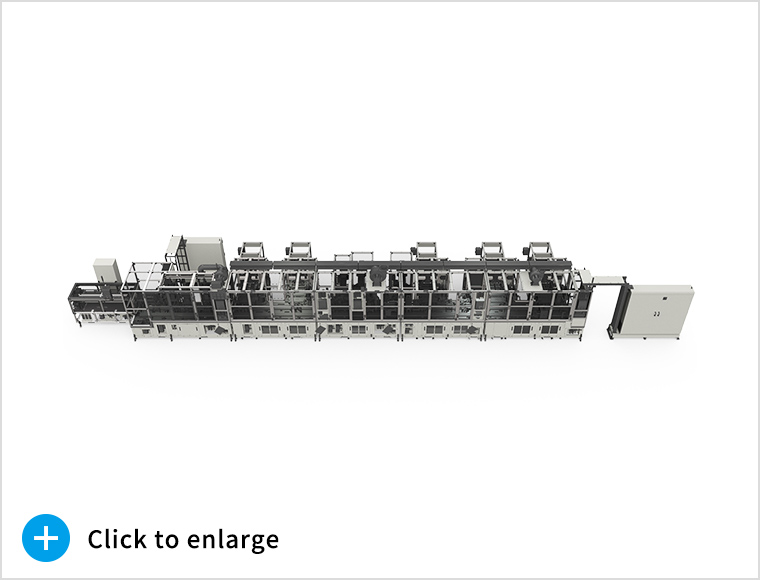

Battery Assembly Line

Shinmei's battery assembly line produces lithium-ion batteries used in hybrid cars and electric vehicles. The line assembles and secures components like current collectors, gaskets, and terminal plates onto the battery casing.

FACILITY

Facility outline

Machining Room & Inspection Room

5-Axis CNC (YBM Vi40 Ver. II)

Vertical CNC Jig Borer (YBM 950V ver. III)

3D Measuring Machine (Gantry type)

Assembly Room

Class 10,000 cleanroom

*Equivalent to the level of operating rooms and ICUs (Intensive Care Units) in medical facilities

Delivery Record

Toyota Motor Corporation (Headquarters Plant, Motomachi Plant, Kamigo Plant, Miyoshi Plant, Akichi Plant, Shimoyama Plant, Kinuura Plant, Tahara Plant, Chubu Plant), Primearth EV Energy Co., Ltd., Prime Planet Energy & Solutions, Inc., Toyota Industries Corporation, Denso Corporation, Anden Co., Ltd., Aisin Seiki Co., Ltd., Toyota Body Co., Ltd., Toyota Motor East Japan, Inc., Toyota Motor Kyushu, Inc., Toyota Motor Hokkaido, Inc., Hino Motors, Ltd., Daihatsu Motor Co., Ltd., Subaru Corporation, Isuzu Motors Ltd., Daihatsu Kyushu Co., Ltd., JTEKT Corporation, Yamaha Motor Co., Ltd., Akebono Brake Industry Co., Ltd. (in no particular order)

Future

Vision for the future

From parts to production systems: Shinmei's Goal

Shinmei aims to create a business that can produce not just parts and equipment, but also the entire production system for electric vehicles. To achieve this goal, we've recognized that the development of software-related technologies, such as driving support systems and seamless connections with mobile devices, is just as essential as hardware components and equipment. With a production system in place, we are moving beyond simply manufacturing products upon request and instead, leading the production of electric vehicles themselves. We are taking steps closer to achieving our goal through various efforts, including improving technology, investing in equipment, and hiring talent.